Saleable yield is the ultimate goal of broiler production in fully integrated production systems. Breed decisions play a fundamental role in the financial outcome of broiler companies and could make the difference between healthy profits or a struggling operation. Cobb’s customers will achieve success when provided with products that enable them to satisfy the needs of their customers and the ultimate consumer. Cobb geneticists understand this very well and have acted, for a very long time, to ensure that our birds deliver as much first-grade meat as possible. As a company, we are aware that improving meat quality from a single angle (genetics, nutrition, management, or processing) will not guarantee success and that a multidisciplinary approach is necessary. Today, Cobb’s products enjoy the position of having the highest meat quality in the industry and we are proud of this accomplishment. This did not happen by chance. It was the result of a carefully planned and executed long-term plan that aimed at protecting the quality of our broiler meat.

In the field, our geneticists provide extensive training and guidance to Cobb’s field selectors to identify any birds that have issues with hard breast muscle. Since all the 2.5 million pedigree birds [1] hatched at Cobb each year are handled individually, we are certain to remove from our production pipeline those that do not meet our strict meat texture standards. Cobb does not stop here: by using a combination of equipment developed in-house by our engineering team [2] and state of the art imagery technology we are able to measure objectively the firmness of the breast meat in each bird that is being considered as a breeder for future generations of Cobb products. This information is kept for later use in breeding decisions.

Every week a dedicated team at Cobb dissects several pedigree birds to evaluate meat quality. A small proportion of birds are identified as having specific meat quality issues like wooden breast, spaghetti breast, or green tenders. Their information is recorded and used, at a later stage, by our geneticists to single out any families of birds that may be more prone to express these issues. We employ sophisticated statistical methods to find out which birds carry the genes that may increase the chance for meat problems in their descendants, even though they appear to be perfectly normal and have passed their individual screening. These birds are removed from our production system to ensure that our customers only receive premium quality products for their operations.

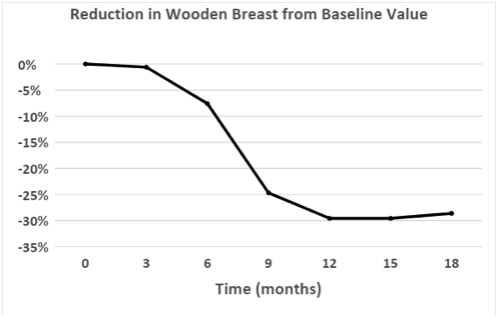

Removing birds with meat texture issues or that belong to families that frequently express these issues has helped Cobb restrain the incidence of wooden breast in our chickens, keeping the incidence low in some lines, or reducing from previous levels of incidence in others. In one of our heavy lines, an 18-month effort resulted in a drop of more than 28% of incidence of wooden breast. When such encouraging results are achieved, we don’t let our guard down. Rather, Cobb continues to capture data on meat quality and to monitor it closely, to protect from deterioration.

Looking into molecular genetics approaches, it is appropriate to say that there is no single gene in the chicken genome that causes wooden breast. Many reputable research groups around the world have found genetic markers that appear to have some influence on meat quality. These results, while scientifically sound, have not yet been translated into actionable steps that broiler genetics companies can take to significantly improve meat quality. Cobb continues to invest in molecular genetics technology, both in-house and through partnerships with universities and research institutes worldwide. This search for the exact genes that will have a major impact on meat quality is one of our funding priorities.

In summary, meat quality has been and will continue to be an integral part of Cobb’s genetics program. We have built a system that can efficiently identify those birds that need to be excluded from our breeding populations and will continue to work with our customers to meet their need of efficient broilers that yield a high percentage of high saleable meat.